LVW GROUP HAS SIX OPERATING UNIT

From Knittting to Finishing

We have 280 circular knitting machines

- Single Knits (Single Jersey, Single Jersey+PU (Spandex), Various Pique Structures, Plated Jersey and Piques, Mini French Terry) (Interloop, Inlay)

- Double Knits (Ribs, Interlocks, Drop needles, Ponte Di Roma, Double face and all are attached with PU (Spandex) & Poly Blends)

- French Terry ( 3-Ply French Terry)

- Terry (Pile and Loop Back Terry Towel)

- Jacquard Machines (Semi-Automatic and Fully Automatic)

- Engineered Stripe Machines

- Small Diameters Knitting Machines

- Single Jersey 16” - 26”

- Interlock 17” - 19”

- Rib 16” - 20”

Daily Dyeing Capacity of 45 tons.

Totally 78 dyeing chambers Batch size ranging from

- 20kg

- 50kg

- 75kg

- 100kg

- 300kg

- 500kg

- 800kg

- 1,000kg

- 1,200kg

- 1,500kg

- 1,800kg

Production Capacity of 500, 000 sets per month.

Can produce Yarn Dye Flat knits, Jacquard Flat knits, Flat knits with spandex Can also produce Flat knits for waistband

8000 Kgs of Daily Capacity.

Mainly Cone Dyeing We can dye any type of yarn in Cone form

Printing Capacity per Day is 8,000 Kgs.

- 3 Flat Screen Printing Machines

- 2 Rotary Printing Machines

- Handles Pigment Printing only

- Can Print up to 10 colors per design

- For discharge and reactive, we have commission printing factory

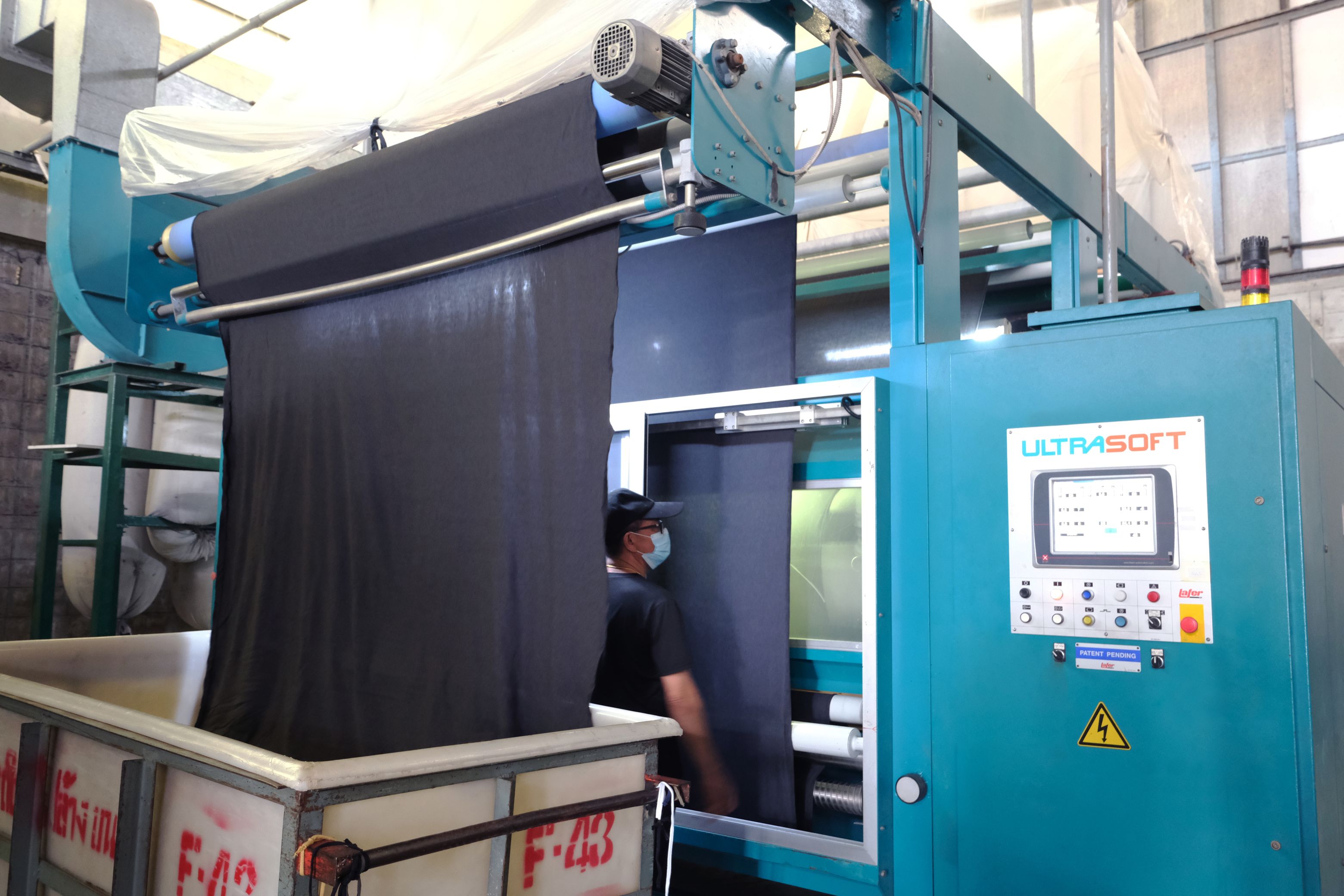

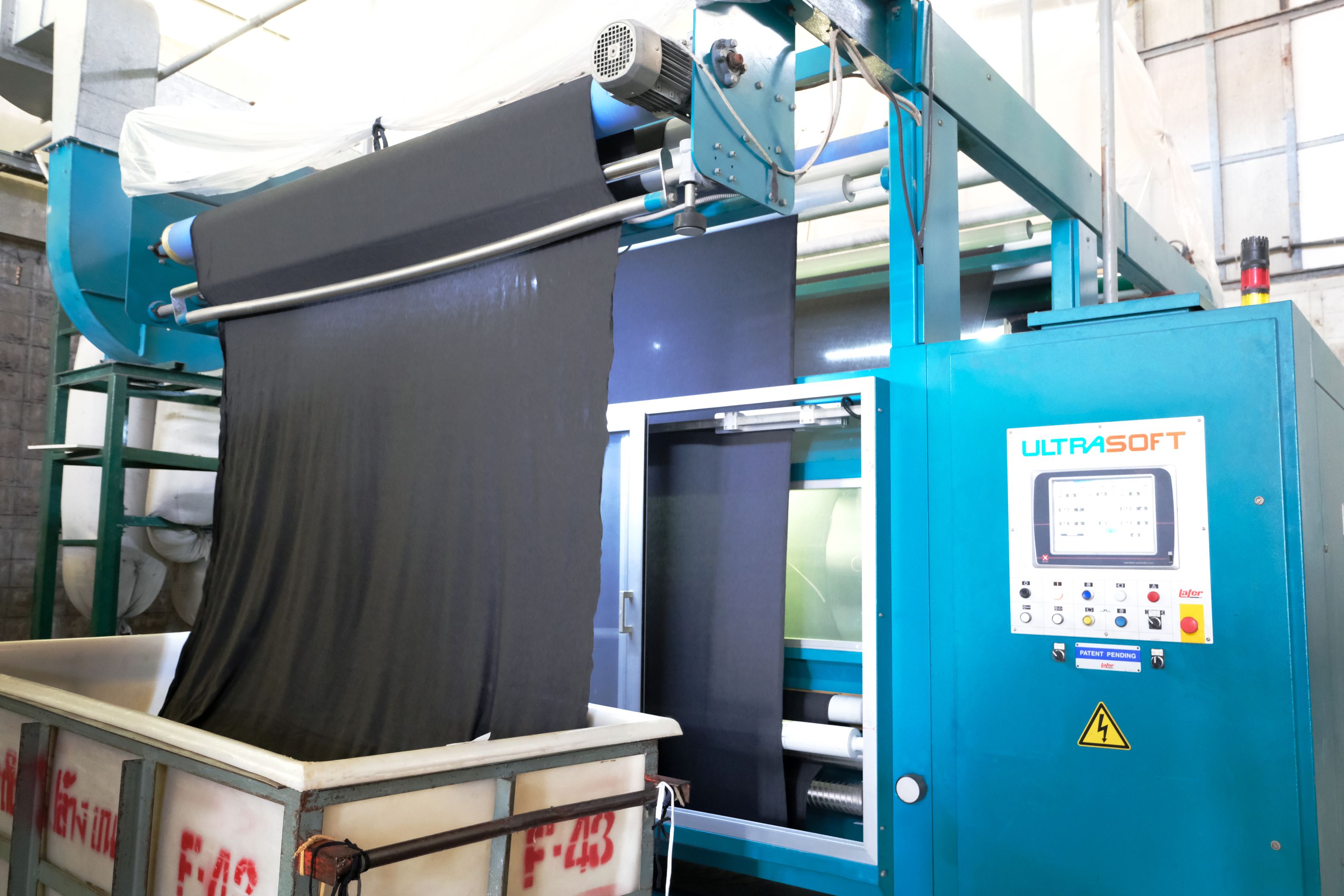

6 Open Width Stenters, can handle fabric as wide as 90" Inches

- 2 Tensionless Dryers

- Open Width Compactors

- 2 Tubular Compactors

- 6 Tubular Calendering Machines

- 2 Tubular High Temp Setting Machines

- 2 Lines of fleecing production units

- 2 Peach Brushing or Carbonizing Machine

- 1 Shearing Machine